240 000 Cakes/8H 1040mm Roller Fried Bag Instant Noodle Production

Line 80g/Cake

Description

Carbon steel, pipe,iron steel, U- steel, stainless steel on noodle

line are purchased from China government big company like Taiyuan

steel group company.

HAERBIN bearing, WANAN motor, GUOMAO speed reducer are all Chinese

most famous brand, we can also customize as customer requires.

Using ABB or Siemens motors, NSK bearing etc.

Electric part, we use Emerson converter,PLC Mitsubishi, touch

screen Wenview to guarantee noodle line quality.

Any special require on noodle line part, our factory can work out a

plan for customizing.

From dough rolling to air cooling, main procedures use VVVF,

photoelectric tracking, PLC program control and frying temperature

controllable.

It has special characteristics on automation, big quantity, energy

efficiency, compact structure, appearance, operation and maintain

convenience etc.

It can realize mass production of bag instant noodle, bowl instant

noodle, cup instant noodle and irregular long noodle while

customizing for you.

Parameter Time

| Item | Time |

| Separate chute | 5-10 lines |

| Cutting ratation speed | 50- 60 R.P.M.(Adjusting) |

| Mixing | 12 minutes |

| Steaming | 80-90 seconds |

| Frying | 75-90 seconds |

| Cooling | 120-145 seconds |

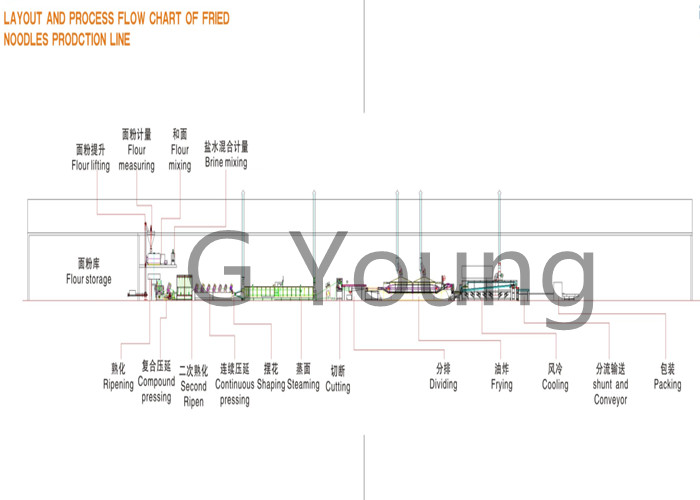

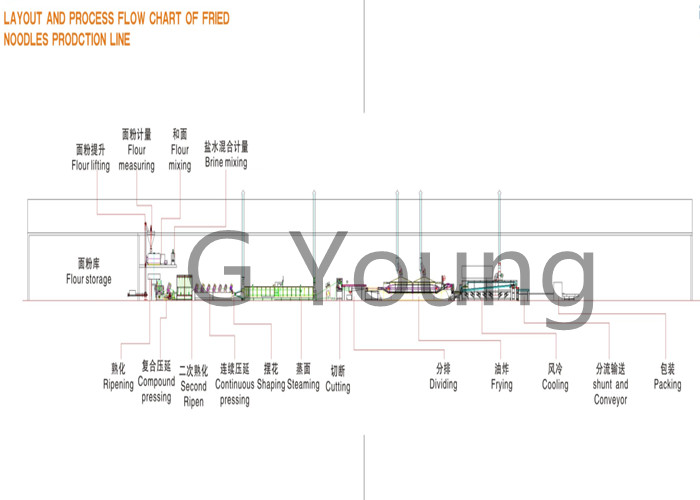

Flow & Main Data

| Alkali mixing&measuring | Flour mixer | Feeder |

1000L/ MOTOR 1.5 KWx3, Pump : 0.75KWx3 Units | pneumatic/Air cylinder type

Duel-Axis and Duel Speed | length 4000 mm

MOTOR : 1.5KW+1.5 kw |

|  |  |

| Compound&Continuous roller | Cooking machine | Cutting/ Folding

Dividing machines |

1st roller is drawbench type, 3rd & 4th Roller is ripple | DIMENSION (L) : 32000 MM Single Layer Type | 4300mm/ MIXER : 0.75 KW

RECYCLE PUMP : 0.75 KW |

|  |  |

| Frying machine | Cooling machine | Electric system |

LENGTH : 12900mm

FRYING TIME : 75--90 Sec | 9 Mtrs. WIND GROOVE WITH EXHAUST FAN 4 KW x 1 unit | BrandSchneider/Kaifeng/Tongli

brand ABB/BRAND SEW |

|  |  |

Features

High degree of automation, frequency conversion speed, Man-machine

interface, PLC control.Fried instant noodle production line.

Dough mixer machine is with double shafts speeds for optimal dough

mixing effect.

Originative structure for single layer or multi-layer steaming

machine keeping temperature proper.

High heat exchange rate in frying keeps no pollution on oil and

lower content oil in noodles.

Beautiful appearance, easy to operate, in line with health

requirements.

The noodle line is with high automation, convenience, low energy

consumption and less space occupation and investment.

The instant noodle production line uses specially designed oil

circulating system of frying machine and auto noodles arrangement

system make the oil temperature distribution more uniform, more

effective and labor-saving.

Our Service

Factory guarantee after sales service and technical supporting all

time through.

1.We make accurate factory layout design according to customer’s

factory size; if the customer needed, we could make workshop design

with electricity power, water supply,gas power, material storage,

final storage, worker’s restroom, etc.

2.Products quality problems in factory’s responsibility,

replacement and repairs will be timely given.

3.Free new production techniques and formulas.

4.On line message feedback and directly form of mail or phone,

making satisfactory solutions in shortest time for all customers.

5.Free project planning and design services.

6.Overseas sending technicians for installations, training and

operating etc.

7. Provide 1 year complete warrantee and life-time maintance.

Click

Noodle line running on

youtube